In the last 150 years, nearly 50,000 scientific publications on Lactic acid bacteria have been published within the scope of SCI and it is reported that 3,453 of these publications are only for 2023 (Web of Science, 2024). Today, thousands of scientists are still studying intensively on the subject and significant discoveries have been made.

Considering that the starter culture market, based on lactic acid bacteria, is at the level of billions globally, it becomes clear how important lactic acid bacteria are.

Unfortunately, it is impossible to make a precise definition and classification (on a family basis) for lactic acid bacteria. Considering recent taxonomic developments and accumulated genetic data, it can be said that they represent ancient Bacillus-like soil organisms adapted to new and nutritionally rich ecological environments.

Although they lose many metabolic activities in the adaptation process; Their effective properties, such as fermentation systems, acid production and acid tolerance, have enabled lactic acid bacteria to compete strongly with other microorganisms.

According to the biological classification;

LABs are members of;

- Bacteria kingdom,

- Firmicutes phylum,

- Bacilli class,

- Lactobacillales order.

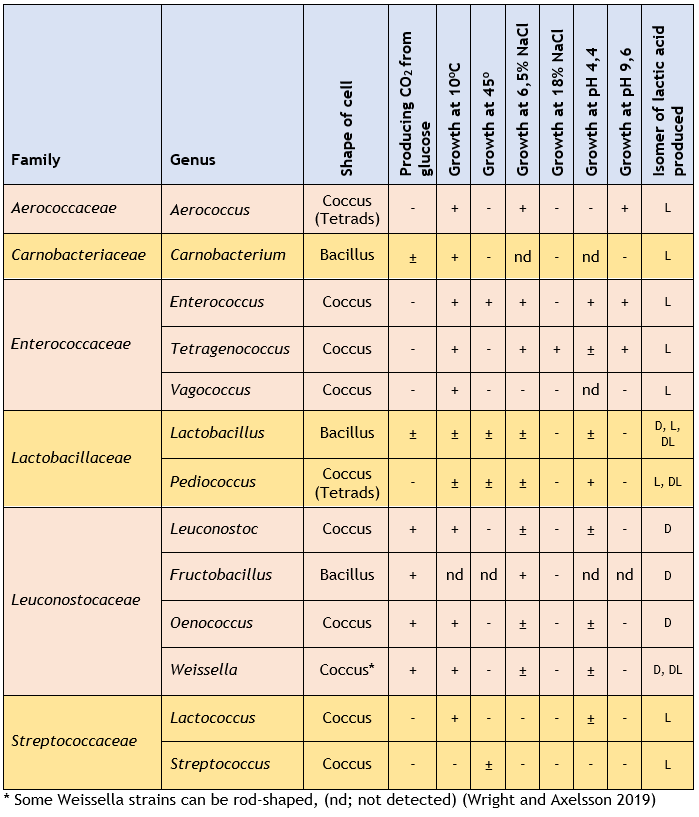

Current classifications and some characteristic features based on families are given in the table.

Mostly Carnobacterium, Enterococcus, Lactobacillus (dairy, meat, vegetables and grain products), Lactococcus (dairy products), Leuconostoc (vegetables and dairy products), Oenococcus (wine), Pediococcus (vegetables and meat products), Streptococcus and Weissella (dairy products) genus lactic acid bacteria are used as starter cultures in the food industry.

Lactic acid bacteria are generally non-spore-forming, heterotrophic, anaerobic, microaerophilic, Gr (+), immobile, rod or spherical-shaped bacteria with relatively high acid resistance. The G+C ratio in their DNA is below 55%. LAB genomes are characterized by small sizes ranging from 1.23 Mb (Lactobacillus sanfranciscensis) to 4.91 Mb (Lactobacillus parakefiri).

By fermenting carbohydrates in a homofermentative or heterofermentative way, they can produce acetic acid, formic acid, ethanol and CO2, although the main product is lactic acid. According to optimum growth temperatures, LAB can be divided into mesophilic and thermophilic.

Mesophilic LAB can grow optimally at 20-30oC, while thermophilic LAB can grow optimally between 30-45oC. This is probably why products from Western and Northern European countries have predominantly mesophilic LABs, while products from subtropical countries have thermophilic LAB.

Milk and plants (vegetables, fruits and grains) form the natural habitats of lactic acid bacteria. However, they can also be found naturally on warm-blooded animals’ mucosal surfaces, such as the oral cavity, intestine and colon.

A LAB member strain can be isolated from many different environments such as humans, plants, animals and dairy products. This indicates that LABs exhibit an extensive distribution and strong adaptation. In addition to the GRAS (Generally Recognized As Safe) status of LABs, increasing antibiotic resistance and the ability to be transferred to pathogenic bacteria pose a risk that should not be ignored.

Since lactic acid bacteria lack cytochrome and electron transport proteins, they cannot obtain energy through aerobic respiration. Therefore, substrate-level phosphorylation reactions during glycolysis are the primary source of ATP.

Although there are significant differences in how some genera and species use and metabolize certain carbohydrates, lactic acid bacteria generally lack metabolic diversity. Lactic acid bacteria can ferment carbohydrates in two ways.

Homofermentative LABs metabolize the carbon source via the Embden-Meyerhof-Parnas (EMP) pathway, producing 2 moles of ATP and 2 moles of pyruvate per mole of hexose. Pyruvate is then reduced to lactate by lactate hydrogenase, converting over 90% of the initial hexose to lactic acid.

Heterofermentative LABs form 1 mole of ATP and at least 50% of lactic acid and 50-30% of ethyl alcohol and/or acetic acid and CO2 by following the pentose phosphate, Leloir pathway and phospho ketolase pathway.

LABs are well adapted to using lactose as a source of energy and carbon and using casein as a nitrogen source. Lactic acid bacteria, which cannot use inorganic nitrogen, can metabolize proteins and peptides to meet their amino acid requirements.

Lactic acid bacteria have highly efficient systems that can reduce casein subfractions to smaller fragments, providing all the amino acids necessary for their growth. In addition to its effects on development, the proteolytic activity of lactic acid bacteria is highly effective in ripening and flavor, especially in cheese production.

In general, it can be said that lactic acid bacteria have very low levels of lipolytic activity. This activity is more effective on mono- and diglycerides. In some cheese varieties and butter (provided that it is not high), lipolysis may be desired to increase the concentration of volatile fatty acids and gain the desired characteristic taste and aroma.

Although citrate metabolism to diacetyl (butter flavor) and acetoin/2,3-butanediol is standard in many LABs, Lactococcus and Leuconostoc bacteria are technologically important.

Citrate metabolism is the most important factor in forming aroma and flavor in dairy products. Citrate metabolism requires large amounts of pyruvate relative to the NAD+ regeneration requirement.

The needed pyruvate is provided by the breakdown of citrate naturally found in milk (~1.5 mg/mL). The important point here is that the pH of the environment must be lower than 6.0 for citrate to be taken into the cell.

There are three main pathways exhibited by LABs on aroma formation in fermented products: glycolysis, lipolysis and proteolysis metabolism. While the main product produced from lactose conversion is lactate, some intermediate pyruvate is alternatively converted to compounds such as diacetyl, acetoin, acetaldehyde or acetic acid.

LAB contributes relatively little to lipolysis, but proteolysis is the key biochemical pathway for flavor formation. The degradation of caseins by rennet enzymes and cell envelope proteinases and peptidases produces small peptides and free amino acids.

For specific flavor development, these amino acids can also be converted to various alcohols, aldehydes, acids, esters and sulfur compounds.

Lactic acid bacteria species used as starter culture in dairy products are given in the table below; (If you are viewing from a mobile phone, select the desktop site version to view correctly)

| Species | Dairy Product | Role | Reference |

| Lactococcus lactis ssp. lactis | butter, cheese, and buttermilk | acidity, bacteriocin production | Akgul (2020), Broome et al. (2003), Wouters et al. (2002) |

| Lactococcus lactis ssp. lactis biovar diacetylactis | butter, gouda, edam, sour cream, buttermilk | acidity and aroma | Akgul (2020), Wood (1997), Leroy and De Vusyt (2004) |

| Lactococcus lactis ssp. cremoris | butter, some cheese types, buttermilk | acidity | Akgul (2020), Weerkam et al. (1996) |

| Streptococcus thermophilus | yogurt, some hard and semi-hard cheese types, | acidity | Broome et al. (2003), Beresford et al. (2001) |

| Lactobacillus acidophilus | yogurt, kefir, butter, and some cheese types | probiotic character | Erkaya et al. (2015), Brigiler-Moarco et al. (2007) |

| Lactobacillus delbrueckii ssp. bulgaricus | yogurt, grana, emmental, mozzarella, taiogga, kefir | acidity | Slaterry et al. (2010), Acculas and Auclair (1983), Dellaglio et al. (1994), Kılıç (2011) |

| Lactobacillus delbrueckii ssp. lactis | some cheese types | acidity | Broome et al. (2003), Giraffa et al. (2010) |

| Lactobacillus helveticus | cheddar, kefir | aroma | Slattery et al. (2010) |

| Lactobacillus casei | some cheese types, kefir | probiotic character | Minelli et al (2004), Kongo (2013) |

| Lactobacillus plantarum | yogurt, some cheese types | probiotic character | Leroy and De Vusyt (2004) |

| Lactobacillus rhamnosus | butter, some cheese types | probiotic character, exopolysaccharide production | Akgul (2020), Coppola et al. (2005) |

| Lactobacillus brevis | feta, kefir | aroma | Terzic-Vidojevic et al. (2015), Leroy and De Vusyt (2004) |

| Lactobacillus reuteri | cheddar | exopolysaccharide production | Lynch et al. (2014) |

| Lactobacillus johnsonii | yogurt | probiotic character | Leroy and De Vusyt (2004) |

| Lactobacillus kefir | kefir | probiotic character | Leroy and De Vusyt (2004) |

| Lactobacillus kefiranofacies | kefir | probiotic character | Leroy and De Vusyt (2004) |

| Leuconostoc mesenteroides ssp. cremoris | butter, sour cream, some cheese types, edam, gouda, kefir | aroma | Akgul (2020), Weerkam et al. (1996) Slattery et al. (2010) |

| Enterococcus faecium | some cheese types, Izmir tulum cheese | aroma, probiotic character | Terzic-Vidojevic et al. (2015), Yerlikaya and Akbulut (2019) |

| Enterococcus faecalis | Iran UF cheese, cebreiro | aroma, probiotic character | Pirouzian et al. (2012), Centeno et al. (1999) |

| Enterococcus durans | Izmir tulum cheese | probiotic character | Yerlikaya and Akbulut (2019) |

| Weissella cibaria | cheddar | exopolysaccharide production | Lynch et al. (2014) |

Here’s an article that might interest you; Starter Cultures; History, Definition and Classification

Be First to Comment